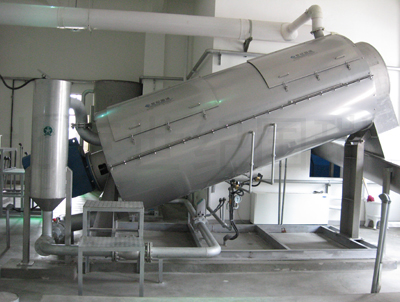

GLT--screw press sludge dewatering equipment

Application scope

Product advantage

·Continuous thickening and dewatering treatment of the sludge is economical and practical, performance outstanding.

·Solid content of dewatered and thickened sludge is up to 20-30% DS.

·This integrative equipment is the ideal machine for the sludge treatment.

Issues raised:

·The special sludge and other toxic sludge were produced from municipal wastewater plants, industrial wastewater plants, and the variety of industrial processes everyday. Those sludges must be dewatered first for future treatment process.

·The sludge, which is without dewatering process, will be collected and recycled difficultly, even cannot treated by incineration nor composting for agricultural purposes.

·The expense of transportation increased continuously, the urgent necessary condition about solid content of sludge after treated and no unwanted inorganic impurity exist would applied.

Solution to these problems: use GLT—screw press sludge dewatering equipment

Working Principle

GLT screw press dewatering equipment has low-rotating speed, hermetical structure and can be continuously operated.GLT consists of Wedge-shaped cylindrical stainless steel filter and stainless steel screw-shaft with variable pitch, variable axial-radial axis and reasonable changed gradient.

The slurry with solid content 0.5%, which is come from sedimentation tank, condensing tank or decomposition tank, passes through jet fluidic feeding device, mixes with flocculant solution , then be transported into stirring reactor. When the concentration of homogeneous is stable, then the slurry flows into dewatering machine.

The sludge will be taken and raised by screw-shaft from bottom to the top and gradually squeezed during this conveyance. Because of the converted triangle design at the top of machine, the press force increase to the maximum level at there. The final solid content of the sludge can reach 20%--30%DS. The filtrate percolates through the filter and screw-shaft. In order to discharge filtrate successfully, the installation tilt angle of dewatering machine is 22o. Sludge dewatering machine equipped with pre-set automatic cleaning device, Mechanical operation and the effect of dewatering will not be affected in the cleaning process.

This system equipped with a fully automatic powder / liquid flocculant preparation/delivery device, the preparation of the flocculant can be continuously generated by single fully automatic equipment. New technical performances are distinguished from traditional method, which is depending on centrifuge-based, belt-pressing, vacuum-suction and board-pressing. High efficiency of dewatering with low energy required. GLT is suitable for various industries of different types of slurry dewatering requirements.

GLT enrichment technology dehydration device parametric mapping

| Technical parameters as follows: |

type | Solid content of pre-treat slurry(%DS) | Handling capacity (m3 /h) | Output quantity (kg/h) | Power(kw) | Rotation speed(rmp) | Whole weight of operation(kg) |

GLT-1 | 0.5-5 | 2-6 | 8-260 | 2.24 | 0.8 | 3568 |

GLT-2 | 0.5-5 | 6-10 | 24-400 | 2.24 | 0-8 | 3568 |

GLT-3 | 0.5-5 | 8-15 | 32-600 | 3.04 | 0-5 | 4266 |

GLT-5 | 0.5-5 | 20-25 | 80-1000 | 4.04 | 0-5 | 5560 |

| Installed-size table : |

type | A | W | W1 | W2 | H | H1 | H2 | α o |

GLT-1 | 4072 | 1316 | 700 | 300 | 2457 | 1493 | 240 | 22 |

GLT-2 | 4652 | 1316 | 700 | 300 | 2457 | 1493 | 240 | 22 |

GLT-3 | 4571 | 1433 | 700 | 300 | 2463 | 1500 | 240 | 22 |

GLT-5 | 4780 | 1910 | 1000 | 475 | 2980 | 1540 | 240 | 22 |

type | L | L1 | L2 | L3 | L4 | D1 | D2 |

GLT-1 | 4036 | 2439 | 2759 | 371 | 614 | 922 | 922 |

GLT-2 | 4662 | 3019 | 3339 | 371 | 614 | 922 | 922 |

GLT-3 | 4583 | 2931 | 3358 | 371 | 614 | 1066 | 922 |

GLT-5 | 4840 | 3350 | 3900 | 150 | 485 | 1460 | 1460 |

type | DN1 | DN2 | DN3 | P1 | P2 |

GLT-1 | 80 | 100 | 125 | 2019 | 1126 |

GLT-2 | 80 | 100 | 125 | 2308 | 1260 |

GLT-3 | 80 | 100 | 150 | 2810 | 1456 |

GLT-5 | 100 | 100 | 200 | 3706 | 1854 |

| note:DN1, DN2, DN3 of the standard flange, nominal pressure for PN10 |

| GLT-type sludge dewatering device has novel design, outstanding performance. |

Advantageous factors: |

| · | Conjugate with wastewater treatment plant system, to form one continuous operation system. |

| · | Use high abrasion resistance stainless steel mesh, but not use fabric filter. |

| · | Automatic rotary self-washing function is fitted. |

| · | Compact structure occupies less area. |

| · | Residue of sludge dumping directly into the container |

| · | Screw-shaft with low speed rotation, therefore no abrasion and noise would be made. |

| · | Minimum maintenance costs. |

Drive components less slow speed, less energy consumption. | |

| · | Drive motor is almost no need for maintenance. |

| GLT sludge dewatering devices other advantages: |

| · | Whole equipment was made of stainless steel, high resistance for abrasion and corrosion. |

| · | Low operation and maintenance costs. |

| · | Fully automatic operation. |

| · | High cost performance. |

| · | Powerful capability of treatment. |

| · | Hermetically sealed structure causes no disgusting odor leakage. |

| · | With all English graphics operation interface, touch screen display. |

| · | Dewatered sludge with high solid content, less flocculant consumption with low-cost treatment. |

Tel:

Tel:

010-87582092/93

Address : 03-09, First Community of Fengzhu Yuan, No. 18,Jiaomen,Fengtai District, Beijing

Address : 03-09, First Community of Fengzhu Yuan, No. 18,Jiaomen,Fengtai District, Beijing

Web : www.cgeet.com.cn

Web : www.cgeet.com.cn

E-mail :cgeet@cgeet.com.cn

E-mail :cgeet@cgeet.com.cn